|

|

| |

|

Welcome all OEM/ODM Projects |

|

|

|

| |

|

|

| |

We have the

experience, capability, and R&D resources to make any

OEM/ODM integration a glowing success! SupTronics is an

extremely versatile one-stop solution provider with the

ability to bring your concepts and ideas into viable

solutions. We work with individuals and companies at all

stages of design and manufacture, from concept to finish, in

a highly focused effort to bring industry level products and

services to you.

Once customer provides us with concept information and

detailed specifications, we will notify them of the total

cost for design, prototyping, and estimated cost per unit

before the project begins. SupTronics will work with

customers until they are satisfied and all original design

requirements are met, and the product performs exactly to

customers' expectations. SupTronics is your one-stop shop

for new product development or product improvements. Please

contact us for your next product development project. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

SupTronics Technologies

Offering |

|

|

|

| |

|

|

| |

In order to

meet the market's demand and provide the suitable solution,

SupTronics offers board level and system level customized

design and integration service for your product development.

- System engineering

- PCB hardware design

- Mechanical design

- PCBA Prototyping

- Manufacturing and Assembly

- Integrated component procurement

- BOM cost reducation service

- Plastic and metal molding

- Compliance and certification

- Quality assurance

- Logistics |

|

| |

|

|

| |

|

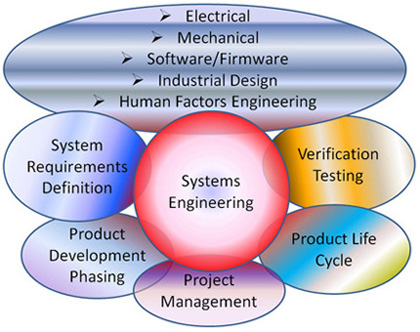

System Engineering

|

|

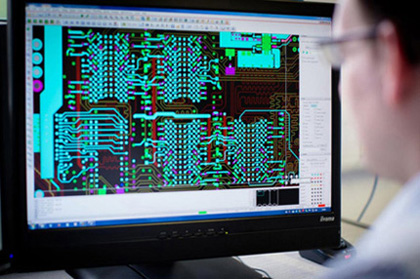

PCB Hardware Design |

| |

|

|

We

work closely with you to understand your project

needs, providing systems level consulting,

architectural study, and professional management

services tailored to the needs of your project.

|

|

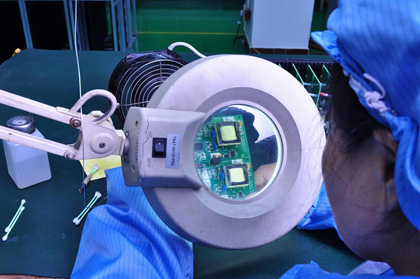

SupTronics has a full staff

of PCB engineers and designers with strong expertise

in advanced, high-speed, complex board design and

experience on over 500+ PCB assembly designs.

|

| |

|

|

|

Mechanical Design

|

|

PCBA

Prototyping |

| |

|

|

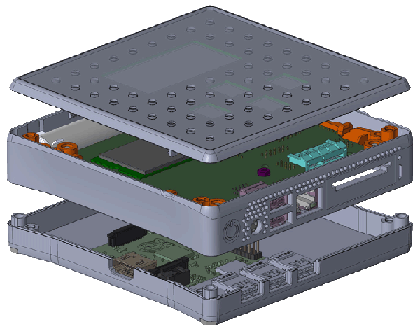

SupTronics' in-house mechanical design and assembly

capabilities include ruggedized box build using

advanced metal and plastic injection molding. Our

processes meet the most exacting enclosure EMI

protection, Thermal dissipation and industrial

environment operation requirements.

|

|

SupTronics offers one-stop

and turn-key PCBA prototype service, including PCB

fabrication, components procurement, and PCB

assembly with the most reasonable price. We have

sufficient stock for common components and maximum

15 days lead time for PCBA with components from

OPL.

|

| |

|

|

|

Manufacturing and

Assembly |

|

Integrated component

procurement |

| |

|

|

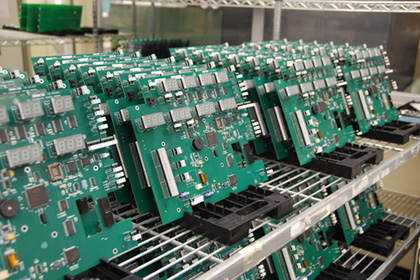

SupTronics undertake both Box Build assemblies and

Sub-assemblies for customers from various industries

ranging from consumer electronics,

telecommunication, audio and video to medical,

computer, lighting etc...

- Handing of Ball Grid Array and Chip

-On-Board assemblies

- SMT component placements

- Automatic Optical Inspection

- In Circuit testing and Functional testing

- New Product Introduction services

- Complex Box Build solutions

|

|

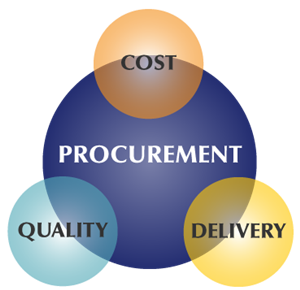

SupTronics offers a full

procurement service to all its customers at no extra

cost. In cases where we are asked to manufacture,

and if required assemble a product which has been

designed and developed elsewhere, just send us a

full bill of materials, along with your technical

files, and we will do the rest. Our team provides a

complete procurement service using a well-refined

supplier list which we have been steadily building

since 2012. We supply all the components needed to

manufacture your PCB and, if required, assemble it

into your free-issue product casing and packaging

ready for sale.

|

| |

|

|

|

BOM cost reeducation

service |

|

Plastic and metal molding |

| |

|

|

|

In order to help our

customers increase their profitability and reduce

component cost, SupTronics provides cost reduction

service customized to fit our individual customers

needs.

Through global sourcing

optimization and proactive planning from your BOM

(Bill of Material), SupTronics offering ultimate

sourcing solutions to businesses procuring raw

materials or finished goods from developing or

developed economies. We implement our experience and

knowledge into each and every aspect of sourcing.

Our team of highly experienced and resourceful

purchasing agents in Asia are able to find the

components you need at the best price available in

the market. We utilize our professional allies and

business partners to reduce the total cost of

ownership for our customers.

SupTronics does

in-depth analysis of the BOM to identify cost

reduction options, including:

- Generating savings from purchase

consolidation

- Identifying lower cost alternates and

providing datasheet

comparison report

- Using Low Cost Country (LCC) sourcing

especially China

- Analyzing current buying prices to spot

abnormal

procurement prices

|

|

SupTronics offers a full

suite of plastic fabrication and molding services,

handling manufacturing, tooling, design and

consulting needs, or just assisting our customers

with the areas that they need. Our engineers can

handle machining, sonic welding, hot stamp welding,

injection molding, and insert molding processes,

working with all types of plastics: ABS,

polystyrene, nylon, polyethylene (high and low

density), and more.

If specialty tooling is required, we work with our

off-shore partners to acquire the necessary pieces,

and either conduct the molding in-house, or provide

the tooling for a client to do their own molding. We

are available for prototype and low volume specialty

molding jobs, so please contact us today.

|

| |

|

|

|

Compliance and

certification |

|

Quality assurance |

| |

|

|

We can also leverage the

level of service another step and also help our

customers to get the CE and FCC certification on

their products.

To reach that we study together the better way to

achieve it offering also our experience in

conducting tests and collecting necessary compliance

documents such as RoHS test report, datasheet, etc.

We have several partners in China to help in this

fields, all of them of proven reliability and

service.

|

|

Quality First,

Customers First

SupTronics' quality assurance procedures include the

regulation of the quality of raw materials, assembly

procedures, testing procedures, production

management and inspection processes. Our QA team is

well-versed in the Plan-Do-Check-Act approach to

quality and we have extensive experience and a

proven track record of customer and independent

audits.

Some of the many ways we ensure product reliability

include:

- Design verification

- In-line failure testing

- Extended burn-in procedure

- Statistical control of errors

- Deep analysis of quality practices

|

| |

|

|

|

Logistics |

|

|

| |

|

|

Through our global supply

chain network we offer demand fulfillment; inventory

management including consignment; continuous product

cost reduction efforts; reserved component stock and

lifetime buy (LTB) programs; and 10 year-plus

product lifecycle support.

|

|

|

|

|

|

|